Firefly welding machine is a tool used by welding contractors because it helps them to gain a competitive edge. A key component of achieving this objective is quality control. Weld quality it’s all about getting a consistent and repeatable finished weld result in line with the Weld Procedure Specification for the project.

Firefly gives contractors more control over the weld they want their welders to produce. The weld parameters can be locked down in Firefly’s control box with the welder having to make only minimal deviations (within pre-set tolerances) to the weld by using Firefly’s remote-control pendant. This approach produces more consistent and repeatable welds reducing the amount of rework required (grinding, gouging, buffing etc). Labour costs are therefore reduced because welders spend less time in rectification works and more time producing quality welds.

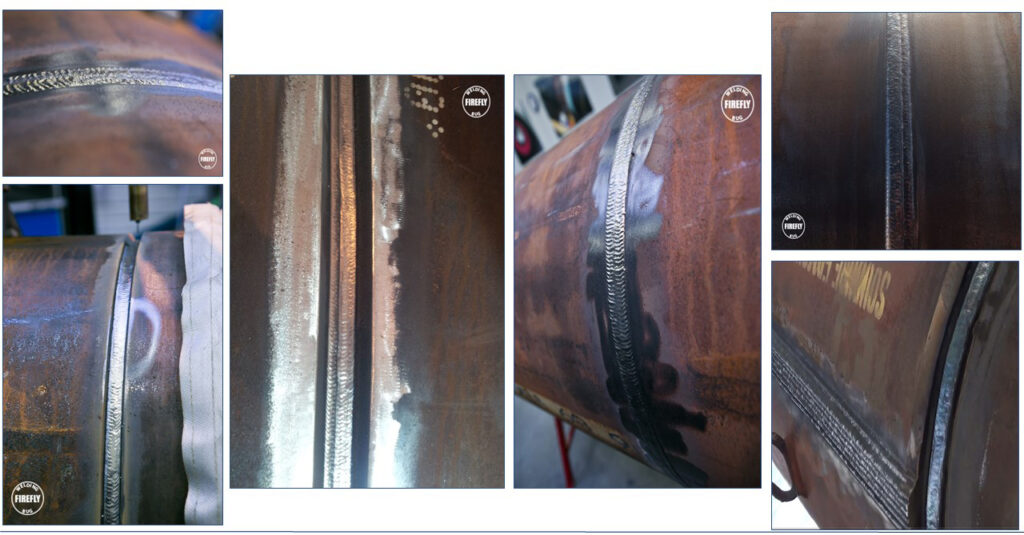

Here are some images of finished welds achieved with Firefly semi-automated welding equipment. With a skilled operator, all the welding results shown are repeatable and consistent with specification.

Circumferential weld results

Horizontal weld results